I am in the process of building an RF Signal Source as per EMRFD Fig 2.27. This is a Hartley design and incorporates 2 oscillators. The first covering a nominal 2-10MHz and the second covering a nominal 10-45MHz.

The Hartley topology is chosen for two reasons. a) The capacitor in the resonator can be fully variable and thus allows a wide range of frequency coverage unlike the Colpitts where, by definition, the feedback capacitors are fixed. b) The oscillator exhibits a reasonably flat output power over a wide frequency range.

Having built the chassis, installed the variable capacitors and cut the panels for the enclosure, I was now in a position to build a rough prototype of one of the oscillators. I chose the lower frequency oscillator. This took me a few hours to build. Since I don't have any of the specified 2N4416 JFETS, I decided to start with an MPF102. I selected sample 2 (Ref JFET experiments blog) since it had a lower pinch-off voltage and higher Idss than sample 1, although not as good in performance as the tested J310. I decided to start with just the 400pf variable capacitor. This should allow easier troubleshooting since there are fewer parts. (refer to the schematic attached).

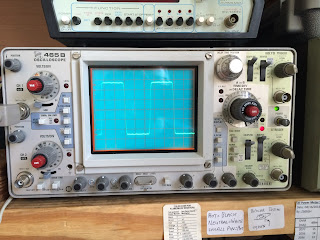

The oscillator powered up first time with no issues. The oscillator turn on voltage Vdd was 1.96V. Maximum output was obtained with a Vdd of 7.58V. Thus there was an excess of current flowing in the drain as Vdd was increased to 12V. The scope output waveform 'looks' clean. I have no way of measuring the harmonic distortion. Could increasing the rail voltage beyond 7.58V result in an increase of harmonic distortion?

The 3 turn link output was first terminated in a 50 ohm feed thru connector which was connected to the scope channel 1. This channel is also fed to the frequency counter. Then the output was connected to the Power Meter.

The oscillator is reasonably stable and certainly acceptable for general measurements and can be improved upon with more careful construction. Measuring at a frequency of 7030.44kHz and starting at 08:30 am the oscillator drifted upwards to 7030.46KHz after 23 minutes (10Hz). The shack door was closed. No thermometer is available. Then with the shack door opened and after another 10 minutes the oscillator was at 7030.73KHz. It then started to rain which presumably lowered the temperature the frequency measured was 7031.02KHz (562Hz). On blowing on the parts with a straw the indications were that the 10pf capacitor was the biggest drift contributor.

As the temperature decreases the oscillator frequency increases. Neither the JFET or the inductor seemed to be significant contributors. No vibration tests were carried out, however it was easy to tune the large capacitor to within 1KHz of the desired frequency. More precise tests needed once the buffer is built.

An error was discovered in the design. The Large 400pF variable capacitor wire runs parallel to the 30pf bandspread capacitor for about 4 inches. Although this capacitor was not connected it changed the oscillator frequency when it's capacitance was varied. Action here is to re-route the large capacitor wire in a different direction.

Tests with the Power meter showed an output variation of just over 1dB from an Fmin output of -1.33dBm at 2810KHz to -0.27dBm (frequency not measured but around 6000KHz). The output power at Fmax of 13663KHz = -0.75dBm. These measurements are in line with those stated in EMRFD and very satisfactory.

Scope measurements

Fmax = 13663KHz (this frequency will decrease as the bandspread capacitors are added)

Fmin = 2810KHz (This frequency will increase as the bandspread capacitors are added)

Fmin Vpk-pk = 6div*0.1 = 0.6V (~0.5dBm)

Fmax Vp-p = 5.5div*0.1 = 0.55V

F(7175KHz) = 0.6V

Power Meter measurements

Fmin = DVM = 1770mV, thus Power = -86.29+(0.048*1770) = -1.33dBm

Fmax = DVM = 1782mV thus Power = -86.29+(0.048*1782) = -0.75dBm

Fpk = DVM = 1792mV thus Power = -86.29+(0.048*1792) = -0.27dBm

Next steps

Reroute the capacitor wiring.

Try different 10pf capacitors to try to improve thermal stability

Try a J310 JFET.

|

| Prototype Hartley oscillator 2.8MHz - 13.7MHz |

|

| Pic showing the large variable and bandspread variable and oscillator circuit with terminations. |

|

| Oscillator set at 7030.64KHz with scope waveform showing no 'visible distortion'. Harmonic level not measured. The feedthrough 50 Ohm terminator on channel 1 can be seen. |

.jpg)